Short Lead Time for 3d Printer Servo Motor - 3 axis Nema 34 stepper motor 1600 oz.in & driver & CNC kit – Longs Motor Detail:

This item includes:

1. 3 pcs Nema 34 stepper motor 1600 oz.in bipolar

2. 3 pcs Stepper motor driver, DM860A, peak 7.8A ,256 Micsteps,replacing M860

3. 3pcs Power Supply 350W-60VDC

4. 1 pc Breakout Board & 1 pc parallel cable

More quatities, More discounts!!

Detailed information :

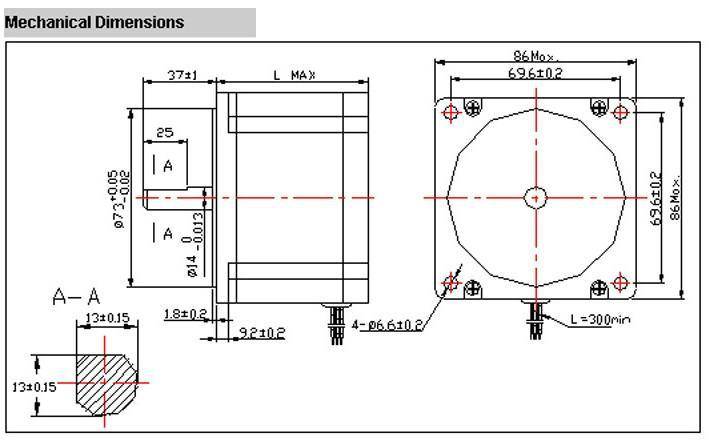

1. Nema 34 stepper motor:

2.Stepper motor driver–DM860A:

Detailed picture:

Introduction:

DM860A is a type of two-phase hybrid stepping motor driver, The drive voltage of which is from 24VDC to 80VDC. It is designed for use with 2-phase hybrid stepper motor of all kinds with 57mm to 110mm outside diameter and less than 8.0A phase current. This circuit that it adopts is similar to the circuit of servo control which enables the motor run smoothly almost without noise and vibration. Hording torque when DM860A run under high speed is also significantly higher than the other two-phase driver, what’s more, the positioning accuracy is also higher. It is widely used in middle and big size numerical control devices such as curving machine, CNC machine, and computer embroider machine, packing machines and so on.

Features:

High performance, low price

Average current control, 2-phase sinusoidal output current drive

Supply voltage from 24VDC to 80VDC

Opto-isolated signal I/O

Overvoltage, under voltage, overcorrect, phase short circuit protection

14 channels subdivision and automatic idle-current reduction

8 channels output phase current setting

Offline command input terminal

Motor torque is related with speed, but not related with step/revolution

High start speed

High hording torque under high speed

3. Power Supply:

The power is 350W, the output voltage is 60VDC

4. Breakout Board:

- Built in DB25 male connector.

- DB25 Output Pin:P1,P2,P3,P4,P5,P6,P7,P8,P9,P14,P16,P17.

- DB25 Input Pin: P10,P11,P12,P13,P15.

- DB25 GND Pin: P18-P25.

- Power supply: +5V DC.

- Built in C-class Optical-coupler.

- High quality with Surface-mount Tech

Whats more, our products are mainly used in CNC machine, Carver machine, Automazation, Printer, Stage lighting and so on. If you have any questions about our products, please dont hesitate to contact me. And I will try my best to support you.

Product detail pictures:

Related Product Guide:

CNC Stepper Motors

Basic Motion Control – An Introduction to Stepper Motors

We have advanced equipment. Our products are exported to the USA, the UK and so on, enjoying a good reputation among customers for Short Lead Time for 3d Printer Servo Motor - 3 axis Nema 34 stepper motor 1600 oz.in & driver & CNC kit – Longs Motor, The product will supply to all over the world, such as: Poland, Singapore, Hungary, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our items and services, please do not hesitate to contact us!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.