Fixed Competitive Price 2 Phase Stepper Motors - stepper motor driver-DM860A – Longs Motor Detail:

Introduction:

DM860A is a type of two-phase hybrid stepping motor driver, The drive voltage of which is from 24VDC to 80VDC. It is designed for use with 2-phase hybrid stepper motor of all kinds with 57mm to 110mm outside diameter and less than 8.0A phase current. This circuit that it adopts is similar to the circuit of servo control which enables the motor run smoothly almost without noise and vibration. Hording torque when DM860A run under high speed is also significantly higher than the other two-phase driver, what’s more, the positioning accuracy is also higher. It is widely used in middle and big size numerical control devices such as curving machine, CNC machine, and computer embroider machine, packing machines and so on.

Features:

High performance, low price

Average current control, 2-phase sinusoidal output current drive

Supply voltage from 24VDC to 80VDC

Opto-isolated signal I/O

Overvoltage, under voltage, overcorrect, phase short circuit protection

14 channels subdivision and automatic idle-current reduction

8 channels output phase current setting

Offline command input terminal

Motor torque is related with speed, but not related with step/revolution

High start speed

High hording torque under high speed

Electrical specification:

| Input voltage | 24-80VDC |

| Input current | < 6A |

| Output current | 2.8A~7.8A |

| Consumption | Consumption:80W; Internal Insurance:10A |

| Temperature | Working Temperature -10~45℃;Stocking temperature -40℃~70℃ |

| Humidity | Not condensation, no water droplets |

| gas | Prohibition of combustible gases and conductive dust |

| weight | 500G |

Pins assignments and description:

1) Connector Pins Configurations

| Pin Function | Details |

| PUL +,PUL- | Pulse signal, PUL+ is the positive end of pulses input pinPUL- is the negative end of pulse input pin

|

| DIR+,DIR- | DIR signal: DIR+ is the positive end of direction input pinDIR- is the negative end of direction input pin |

| ENBL+ | Enable signal: ENBL+ is the positive end of direction input pin. This signal is used for enabling/disabling the driver. High level for enabling the driver and low level for disabling the driver. |

| ENBL- | ENBL- is the negative end of direction input pin. Usually left unconnected (enabled) |

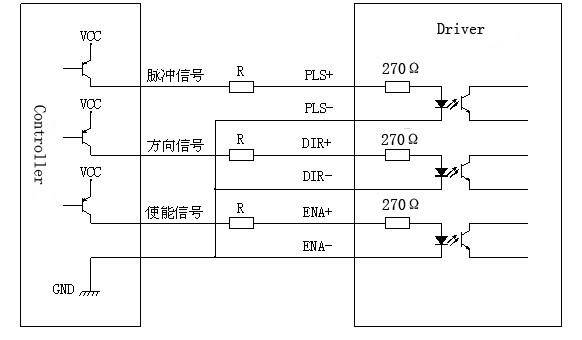

2) Pins wiring diagram:

PC’s control signals can be active in high and low electrical level. When the high electrical level is active, all control negative signals will be connected together to GND. When low electrical level is active, all control positive signals will be connected together to public port. Now give two examples( Open collector &PNP), please check them:

Fig 1. Input port circuit (Yang connection)

PC open connector output

Fig. 2 Input port circuit ( Yin connection)

PC PNP output

Note: When VCC=5V, R=0

When VCC=12V, R=1K, >1/8W

When VCC=24V, R=2K,>1/8W

R must connect in the control signal part .

3.Function choice ( Using DIP pins to achieve this function)

1) Micro step resolution is set by SW 5,6,7,8 of the DIP switch as shown in the following table:

|

SW5 |

ON |

OFF |

ON |

OFF |

ON |

OFF |

ON |

OFF |

ON |

OFF |

ON |

OFF |

ON |

OFF |

OFF |

|

SW6 |

ON |

ON |

OFF |

OFF |

ON |

ON |

OFF |

OFF |

ON |

ON |

OFF |

OFF |

ON |

ON |

OFF |

|

SW7 |

ON |

ON |

ON |

ON |

OFF |

OFF |

OFF |

OFF |

ON |

ON |

ON |

ON |

OFF |

OFF |

OFF |

|

SW8 |

ON |

ON |

ON |

ON |

ON |

ON |

ON |

ON |

OFF |

OFF |

OFF |

OFF |

OFF |

OFF |

ON |

|

PULSE/REV |

400 |

800 |

1600 |

3200 |

6400 |

12800 |

25600 |

51200 |

1000 |

2000 |

5000 |

10000 |

25000 |

50000 |

51200 |

2) Standstill current setting

SW4 is used for this purpose. OFF meaning that the standstill current is set to be half of the selected dynamic current and ON meaning that standstill is set to be the same as the selected dynamic current.

3) Output current setting:

The first three bits (SW 1, 2, 3)of the DIP switch are used to set the dynamic current. Select a setting

Closest to your motor’s required current

|

Output current (A) |

||||

|

SW1 |

SW2 |

SW3 |

PEAK |

RMS |

|

ON |

ON |

ON |

2.80 |

2.00 |

|

OFF |

ON |

ON |

3.50 |

2.50 |

|

ON |

OFF |

ON |

4.20 |

3.00 |

|

OFF |

OFF |

ON |

4.90 |

3.50 |

|

ON |

ON |

OFF |

5.70 |

4.00 |

|

OFF |

ON |

OFF |

6.40 |

4.60 |

|

ON |

OFF |

OFF |

7.00 |

5.00 |

|

OFF |

OFF |

OFF |

7.80 |

5.60 |

4) Semi-flow function:

Semi-flow function is that there is not step pulse after200 ms, the driver output current automatically reduced to 40% of rated output current, which is used to prevent motor h

4. Pins of motor & power:

| Motor and power pins |

1 |

A+ |

Motors wiring | |

|

2 |

A- |

|||

|

3 |

B+ |

|||

|

4 |

B- |

|||

|

5,6 |

DC+ DC- |

Power supply | Power supply :DC24-80VDCThe peak input current can not up to 6A |

5. Mechanical Specification:

To have 20mm of space around ,cannot be placed next to other heating devices. What’s more, avoid dust, oil mist, corrosive gas, heavy humidity and high vibration. (Unit=mm)

pic 3

6. Adjustment of troubleshooting

1) , the status on light’s indication

PWR: green, normal work light.

ALM: red, failure light, the motor with phase short-circuit, overvoltage and under-voltage protection.

2) Troubles

| Alarm indicator | Reasons | Measures |

| LED off turn | Wrong connection for power | Check wiring of power |

| Low-voltages for power | Enlarge voltage of power | |

| Motor doesn’t run, without holding torque | Wrong connection of stepper motor | Correct its wiring |

| RESET signal is effective when offline | Make RESET ineffective | |

| Motor doesn’t run, but maintains holding torque | Without input pulse signal | Adjust PMW & signal level |

| Motor runs wrong direction |

Wrong wires’ connection |

Change connection for any of 2 wires |

| Wrong input direction signal | Change direction setting | |

| Motor’s holding torque is too small | Too small relative to current setting | Correct rated current setting |

| Acceleration is too fast | Reduce the acceleration | |

| Motor stalls | Rule out mechanical failure | |

| Driver does not match with the motor | Change a suitable driver |

7. Driver wiring

A complete stepper motor control system should contain stepper drives, DC power supply and controller (pulse source). The following is a typical system wiring diagram

8. APPENDIX

Twelve Month Limited Warranty

LONGS MOTOR. warrants its products against defects in materials and workmanship for a period of 12 months from shipment out of factory .During the warranty period, LONGS MOTOR will either ,at is option, repair or replace products which proved to be defective.

Exclusions

The above warranty does not extend to any product damaged by reasons of improper or inadequate handlings by customer, improper or inadequate customer wirings, unauthorized modification or misuse .or operation beyond the electrical specifications of the product and/or operation beyond environmental specifications for the product.

Obtaining Warranty Service

To obtain warranty service, a returned material authorization number(RMA)must be obtained from customer service at e-mail:longsmotor@hotmail.com. Before returning product for service. Customer shall prepay shipping charges for products returned to LONGS MOTOR for warranty service, and LONGS MOTOR shall pay for return of products to customer.

Warranty Limitations

LONGS MOTOR makes no other warranty, either expressed or implied, with respect to the product. LONGS MOTOR specifically disclaims the implied warranties of merchantability and fitness for a particular purpose. Some jurisdictions do not allow limitations on how long and implied warranty lasts .so the above limitation or exclusion may to apply to you, however, any implied warranty of merchantability or fitness is limited to the12-month duration of this written warranty.

Product detail pictures:

Related Product Guide:

3 Common Robotics Motors – Servo, DC, and Stepper Motors

CNC Stepper Motors

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Fixed Competitive Price 2 Phase Stepper Motors - stepper motor driver-DM860A – Longs Motor, The product will supply to all over the world, such as: India, Iraq, New Zealand, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.